- Mitsubishi PLC Fx5u

- 10”color touch screen Beijer operator interface terminal (OIT-HMI).

- On-screen programmable Time and Temperature controls w/alarm limits is standard

- Individualized operator (optional), supervisor/engineer or calibration unique sign ins ID/PW for their assigned access levels

- Odometer and resettable Cycle Counter

- USB port for offload of data if desired.

- Powered USB ports (2) for barcode scanner (not included) entry of UDI, sign-on, etc. Keyboard capable as well. Manual input on screen permitted also.

- Data Logging memory of all sign-on access, changes and UDI process data per each cycle. Memory accessible for manual (standard) offloading only. No edits permitted.

- Capability to match recipe with barcoded tooling and barcoded device/paperwork during setup of production.

- Redundant automatic heater over temperature safety cutoff control circuit, Factory Mutual approved controller, 300F cutoff standard.

- Electronic process monitoring with temperature & air pressure sensor fail-safe alarms for parameter recipe settings, PW protected.

- Four (4) dual lead special grade thermocouples for control feedback & accurate individual temperature displays on OIT while providing signals to calibration ports for simultaneous reading.

- Individual thermocouple calibration connector ports. On-screen calibration of each (4) thermocouples. PW protected

- Alarm screen detail history on screen and in memory.

- Low profile LED multi-color signal light for recipe parameter alarms.

- Pressure regulation w/precision manual adjustment & liquid filled precision gauge as well as on screen digital readout

- Pressure validation port for easy calibration guage connection to pressure circuit. On-screen calibration of pressure circuit. PW protected.

- Timer calibration connector (1) 24vdc signal output

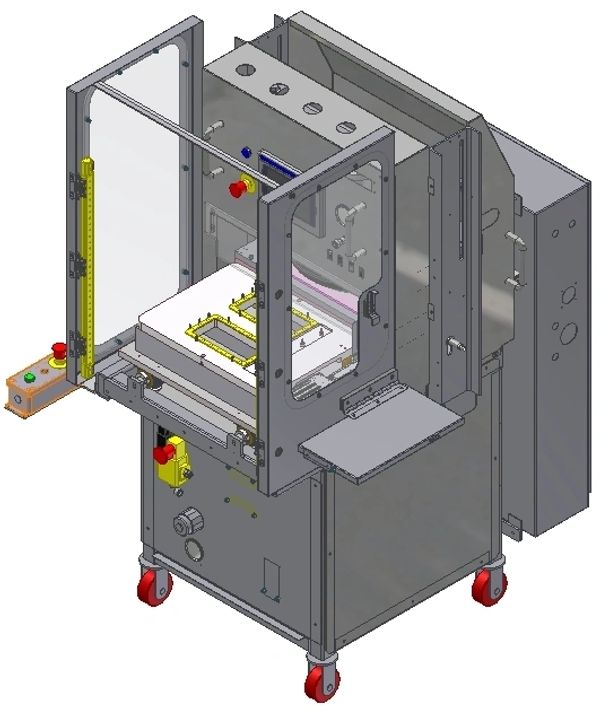

- Eye level controls including 10” color touch OIT/HMI screen, reset(s) and others.

- English or Metric units of measure readouts

- Air Usage 11-13 CFM @ 80 PSI at 4 cycles per minute. Supply @ 100psi with 3/4”+ dia line minimum.

Owner’s manual (1 copy) with operation instructions, maintenance information, recommended spares list, schematics, Atlas Vac calibration document and Atlas Vac PLC programs on USB flash drive. Sealer is ready for operation upon connection to air and electric power; air filter included. Any additional FAT, or other documents and procedures, may require additional charge based on scope and hours needed to complete.

Tooling nests not included, quoted separately .